Pipe caps 'Material problems:

Materiae propter caput debet electus secundum pertinet signa et cubits et mechanica proprietates et eget compositionem debet occursum consilium requisita. Autem, interdum ex aliqua problems, ut defectus in ipsa materia vel improprium materia lectio, caput ut habeat qualitas problems durante usu, ut rimas, deformatio, etc.

SOLUTIO:

I. Stricte control emptio de bonis vitare usum non-vexillum materiae;

II. Confirmare materiam inspectionem et qualis imperium mensuras superiores ut reprehendo an materiae habent defectus;

III. Elige idoneam materiae ad vitare Mismatches.

Finem caps processum problems:

In vestibulum processus in capite, processus imperium est quoque valde magna. Si processus imperium non est severus, problems ut dimensiva deviationis et pauperes Welding qualis potest fieri.

SOLUTIO:

I. Stricte control processus parametri ad curare accurate de perfecta uber magnitudine;

II. Confirmare ad vigilantia processu parametri et qualitas imperium in vestibulum processus ne et rectam deviationes tempore;

III. Confirma qualitas inspectionem de welding processu ad curare qualitas ad weld.

Aliquam ferro pipe caps (finem caps) Design problems:

Consilium capitis potest habere defectuum, ut mismatched geometricae dimensiones et inconveniens structuram, quae paulatim exposita in tempore.

SOLUTIO:

I. Per consilium processus, factores ut usum environment et operantes condiciones esse plene considerari, et consilio debet ferri cum pertinet signa et cubits;

II. Design rationabile sustinet et ferre structurae vitare nimia accentus concentration;

III. Optimize caput structura vitare problems ut aer lacus et fregisset ex consilio problems.

In summary, the problems that may arise in the manufacture of heads mainly include material selection, process control, design defects, etc. For this, we can prevent and solve these problems by strengthening quality inspection, strict process control and optimizing design, so as to avoid quality problems and safety hazards.

Introductio

| Pipe caps | |

| Item | Steel pipe caps |

| Vexillum | Asme / Ansi B16.9, Din2650,2615,2616,2617, Jis B2311, 2312,2313, en 10253-11, En10253-2, GB |

| Materia | Carbon Steel (ASTM A234WPS, A234WPC, A420 Wpl6): (St45.8 A105 A106 STG42) Alloy Steel (ASM A234 WP12 / WP11 / WP22 / WP5 / WP9 / WP91) Steel immaculatam (ASTM A403 WP304 / WP304L / WP316 / WP316L) |

| Superficies | Diaphanum oleum, calidum galvanized |

| Genus | TORMENTUM |

| magnitudo | NP I / 2-12 " |

| Delivery Tempus | Intra 5-30 diebus post acceptam PROMUTUUS |

| Stipare | Ligneus |

| Applicatio | Petrochemical & Gas industria, eget, machinery, electrica potentia, navem aedificationem, constructione aqua opera, valvae industria. |

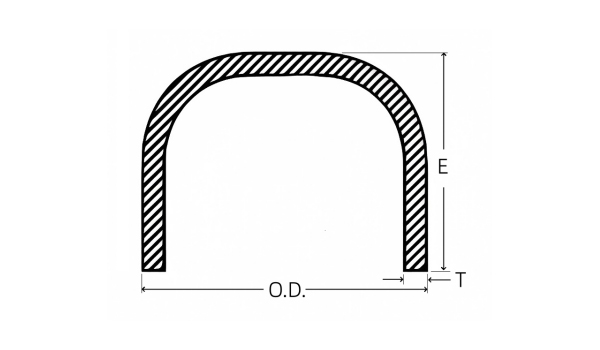

Dimensionem Ansi B16.9 (S / Ransi B16.28)

Unit: inch

| Nominal pipe magnitudine | Extra diameter | Murus crassitudine schedule | Longitudo | |||

| T | ||||||

| Np | O.D. | 5s | 10s | 40s | 80s | E |

| 1/2 | 0.840 | 0.065 | 0.083 | 0.109 | 0.147 | 1.00 |

| 3/4 | 1.050 | 0.065 | 0.083 | 0.113 | 0.154 | 1.00 |

| 1 | 1.315 | 0.065 | 0.109 | 0.133 | 0.179 | 1.50 |

| I 1/4 | 1.660 | 0.065 | 0.109 | 0.140 | 0.191 | 1.50 |

| I 1/2 | 1.900 | 0.065 | 0.109 | 0.145 | 0.200 | 1.50 |

| 2 | 2.375 | 0.065 | 0.109 | 0.154 | 0.218 | 1.50 |

| II 1/2 | 2.875 | 0.083 | 0.120 | 0.203 | 0.276 | 1.50 |

| 3 | 3.500 | 0.083 | 0.120 | 0.216 | 3.000 | 2.00 |

| III 1/2 | 4.000 | 0.083 | 0.120 | 0.226 | 0.318 | 2.50 |

| 4 | 4.500 | 0.083 | 0.120 | 0.237 | 0.337 | 2.50 |

| 5 | 5.563 | 0.109 | 0.134 | 0.258 | 0.375 | 3.00 |

| 6 | 6.625 | 0.109 | 0.134 | 0.280 | 0.432 | 3.50 |

| 8 | 8.625 | 0.109 | 0.148 | 0.322 | 0.500 | 4.00 |

| 10 | 10.750 | 0.134 | 0.165 | 0.365 | 0.500 | 5.00 |

| 12 | 12.750 | 0.156 | 0.180 | 0.375 | 0.500 | 6.00 |

Condita in MMVII et ad Longyou oeconomica progressionem zonam, Zhejiang provincia, in MMXXII. Covers aream 130,000 quadratum metris, magis quam XXX productio lineas, CCC operarios, XX R & D populus, XXX inspectionem et annua, XX R & D populus, XXX inspectionem et annua output de 50.000 talentorum XXX.

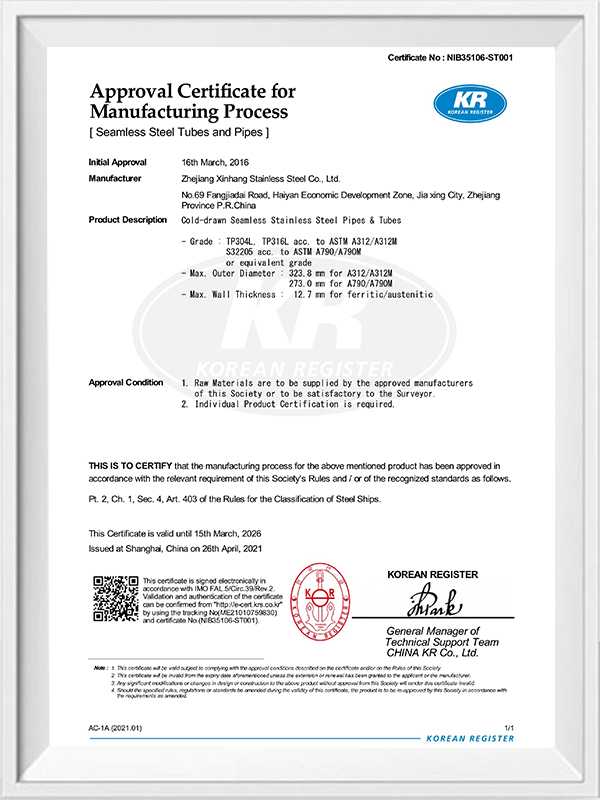

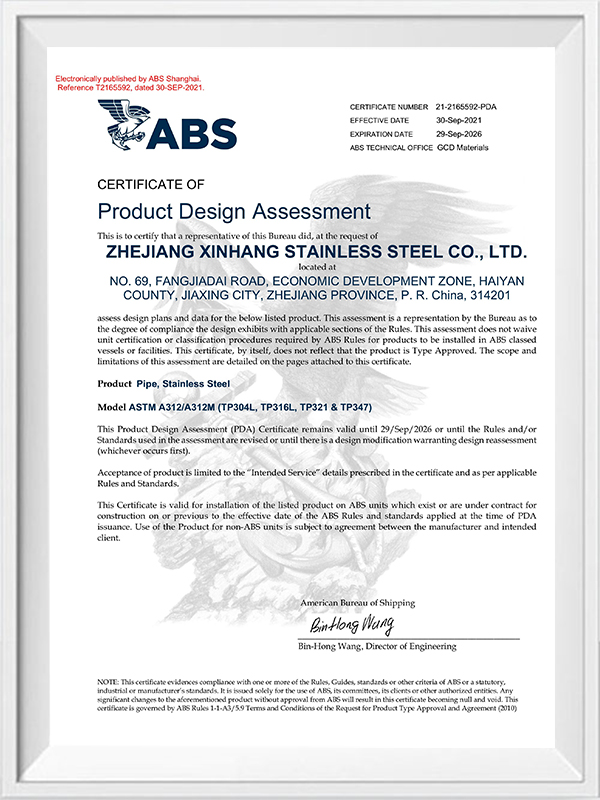

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (Abs): British Register of Shipping (LR), Deutsche Veritas (GL), Bureau veritas Society (BV), Det Norske (DNV), Coreanica Register of Shipping (KR) officina certification.

Pelagus products includere immaculatam ferro, pipe caerimonias, flanges, valvulae, etc., quae late in PETROLEUM, chemical industria, nuclei industria, urget, shippuilding, nuclei, cibo, saltu, electrica, et alimentis, mechanica apparatibus, et aliis agris. In comitatu adhaeret ad corporatum tenet de "qualis est superessendam, fama pro progressionem" et animo serves omnis mos creare win-vincere situ.

Optimum flare instrumentum electionis pro immaculata ferro Tubing Utere summus leverage 37° (AN/JIC) vel 45° (SAE) subtilius instrumentum ad ferrum ignitum aestimatum est, paribus drom...

VisumSolum versus: quomodo ferro intemeratam pactionem tibiam sine saccharo et scillam? Fistula enim ferro incorruptissima opus est, certissima via ad emundandum, corrosio repugnans, rimis stri...

VisumDirectum responsum: quid "canalem ferream immaculatam pressionem rating" revera significat? Fistula ferrea immaculata unam pressionem universalem rating non habet. Recta "incorrupta ...

VisumNos te numquam participes vestri email oratio et vos

Potest opt e aliquo tempore promittimus.