Calor exchanger fistulae sunt ad refrigescant, æstus, seu reheat fluidorum, vapores et aer. Calor exchanger fistulae ludere a vitalis munus in facilitating ad calorem translatio processus per enabling in commutatione scelerisque industria inter processus fluidi et testa-latus fluidum.

Ut possit transferre calefacere bene, pipe debet habere bonum scelerisque conductivity. Quia calor transfertur per fistulam a calidum ad frigus parte, est temperatus differentia per latitudinem tubi. Quia pipe materiae habent diversas tendentias ad thermally expand ad diversas temperaturis, scelerisque passiones fieri per operationem. Hoc non includit aliqua passiones fecit a summo pressura generatae per fluidi ipsum. Tubus materiam debet esse compatible cum testa-tubo parte fluidi super diu terminus sub operating conditionibus (temperatus, pressura, pH, etc.) ad minimize deteriori ut corrosio.

Improprium Tubus Material Electio potest consequuntur in tubo leakagium inter testa et fistulam utrimque, unde in fluidi crucem-contaminationem et pressionem damnum. Scilicet, cum pipe est sub pressura diu, lassitudine non fieri in tempore, unde in ultrices. Cum hoc fit, quam ad reparare calor commutationem tubulis in calor exchanger?

Leakage of calor commutationem fistulas in pressura vasa plerumque occurrit in duo loca, unum est nexum de tubulis, et alia est ad leakage fistulae ipsum.

(I) Leakage ad immaculatam ferro calor exchanger fistula connections

Sunt tria principalis modi ad connectens fistula et fistulam laminas: expansionem articulis, welding, welding et expansionem articulis. Ob fluctuatione temperatus et pressura et inaequalitatem deformatio temperatus differentia, expansion pipe causat tiballium ad trahendum off, discoperiet, et Leak a fistula sheet. Complementary Expansion potest ad eliminate in leakage. Si inefficax, fieri potest. Intellectus expansion non potest esse plus quam ter, aliter hoc faciam in materia in tubo laminam foraminis obdurare debitum ad frigus opus et facti minus stricta.

Si expansion est inefficax, et tibia oportet reponi vel volutpat. Notandum quod post welding, in circuitu fistulae opus ad expanded iterum, quod scelerisque expansion et contractionem in fistula sheet post welding et causa lacus in expansione articulis alterius in circuitu fistulae. Si fistulas fistulas fistulas fistula sheet stillante, potest reparari a molere et reficiendas ad weld.

(II) et pipe se stillante

Ex corrosio, abrasione, exesa, sedimentation corrosio, et alias causas, calor commutationem tubulis saepe causa rimas, perforationes, et effudit in tubulis. Leakage tibia ipsa non reparari in normalis adiunctis. Si numerus stillante stillante fistularum non est magna, vos can utor conico metallum plugs ut angustos utraque fines pipe os. Si pressura in tibia latus est altum, plug eam arcte et deinde plura reliability. Longitudo metallum plug plerumque bis interiore diameter pipe diametri parva aequalis LXXXV% interioris diameter et taper 1,10.

Durness plug materialis minor vel aequalis duritie tibia. Cum plugging fistulae ad eliminate evacuat, numerus Pipes plugged non excedunt X%. Cum autem finis immaculatam ferro calor commutationem fistulam laedi, ducta fistulam instaurationem modum potest etiam esse. Hoc est quia elongatio rate de immaculatam ferro tubo est XL% ~ XLV%. Cum totalis elongatio ducta fistulam non excedat XII%, tubo potest duci multiplex temporibus.

Introductio

| Item | Immaculatam ferro calor exchanger fistulam / pipe | |

| Vexillum | Asma213, ASTMA312, ASM A269, Din17456, En10216-5, En10297-2, Jisg3459, Jis3463 aut consuetudine | |

| Materia | TP304/304L/304H, 316/316L, 321/321H, 317/317L, 347/347H, 309s, 310s, 2205, 2507, 904L (1.4301, 1.4306, 1.4948, 1.4401, 1.4404, 1.4571, 1.4541, 1.4833, 1.4878, 1.4550, 1,4462, 1,4438, 1,4845) | |

| Superficies | Expolitus | |

| Figura | Per fistula / tubo, cocta fistulae | |

| Genus | Frigus volvens aut frigus instructa | |

| Dispensando ministerium | Caput secans, rightinging, secans, molere, lubricatae, calor curatio, gradus degreasing | |

| magnitudo | Longitudo | 6M aut secundum Lorem scriptor petitionem |

| PRAETOR | OD: 12.7mm ~ 630mm Wt: 1.65mm ~ 50mm | |

| Delivery Tempus | Intra 5-30 diebus post acceptam PROMUTUUS | |

| Sarcina | Ligneus casibus | |

Processu productio

.jpg)

Aliquam Steel compositionem mensam

| Pario | Gradus | Chemical compositionem (%) | ||||||||

| C | Si | Mn | P | S | Ni | Credo | MO | N | ||

| Austenititic Aliquam Steel | 201 | ≤0.15 | ≤1.00 | 5.50-7.50 | ≤0.060 | ≤0.030 | 3.50-5.50 | 16.00-18.00 | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 6.00-8.00 | 16.00-18.00 | |||

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.00-10.50 | 18.00-20.00 | |||

| 304L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 9.00-13.00 | 18.00-20.00 | |||

| 305 | ≤0.12 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.50-13.00 | 17.00-19.00 | 0.12-0.2 | ||

| 309S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 12.00-15.00 | 22.00-24.00 | |||

| 310S | ≤0.08 | ≤h.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.00-22.00 | 24.00-26.00 | |||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.00-14.00 | 16.00-18.00 | 2.00-3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 12.00-15.00 | 16.00-18.00 | 2.00-3.00 | ||

| 317 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 12.00-15.00 | 18.00-20.00 | 3.00-4.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 11.00-15.00 | 17.00-19.00 | |||

| Ferricis immaculatam ferro | 409 | ≤0.08 | ≤1.00 | ≤1.00 | ≤0.045 | ≤0.030 | ≤9.00-13.00 | 10.50-11.75 | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.030 | ≤0.60% | 16.00-18.00 | |||

| 430lx | ≤0.03 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.030 | 16.00-18.00 | 0.75-1.25 | 0.1-1.0 | ||

| Martensitic Aliquam Steel | 410 | ≤0.15 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.030 | 11.50-13.50 | |||

| 410s | ≤0.08 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.030 | 11.50-13.50 | ||||

| 420 | 0.16-0.25 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.030 | 12.00-14.00 | ||||

| 440a | 0.60-0.75 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.030 | 16.00-18.00 | ||||

| Duplex Stainless ferro | 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.040 | ≤0.030 | 4.50-6.50 | 21.00-24.00 | 0.08-0.2 | |

| 2507 | ≤0.03 | ≤0.80 | ≤1.20 | ≤0.035 | ≤0.020 | 6.00-8.00 | 24.00-26.00 | 3.00-5.00 | 0.24-0.32 | |

Condita in MMVII et ad Longyou oeconomica progressionem zonam, Zhejiang provincia, in MMXXII. Covers aream 130,000 quadratum metris, magis quam XXX productio lineas, CCC operarios, XX R & D populus, XXX inspectionem et annua, XX R & D populus, XXX inspectionem et annua output de 50.000 talentorum XXX.

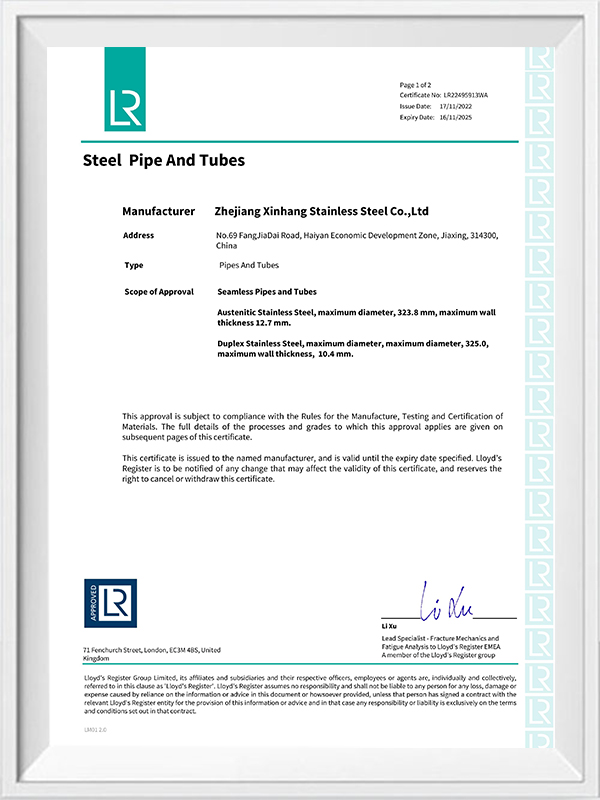

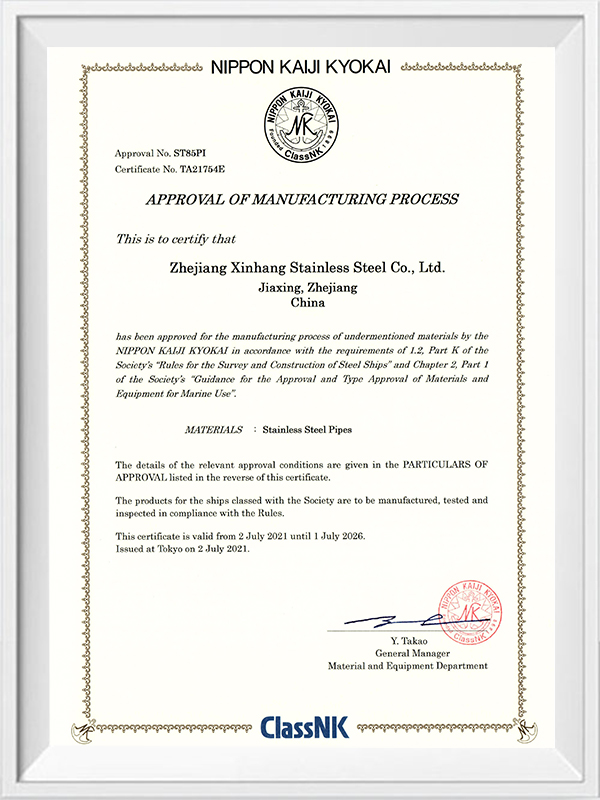

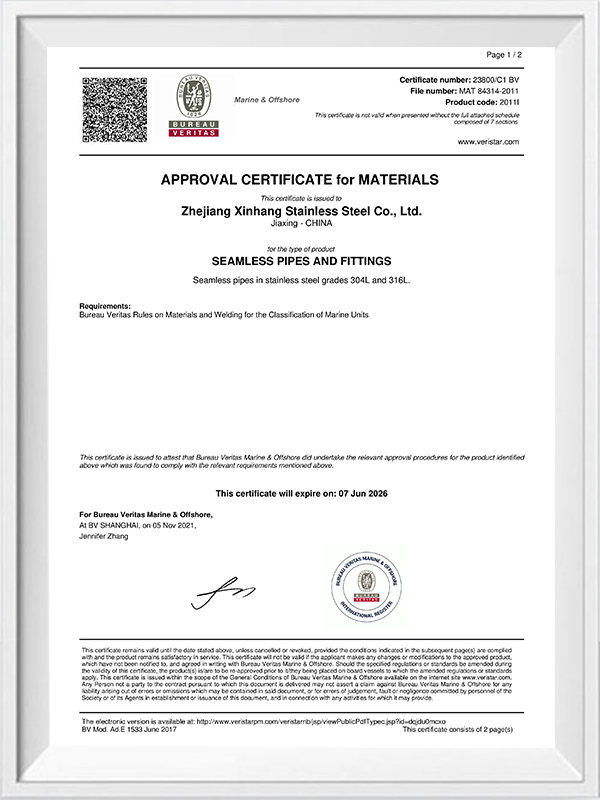

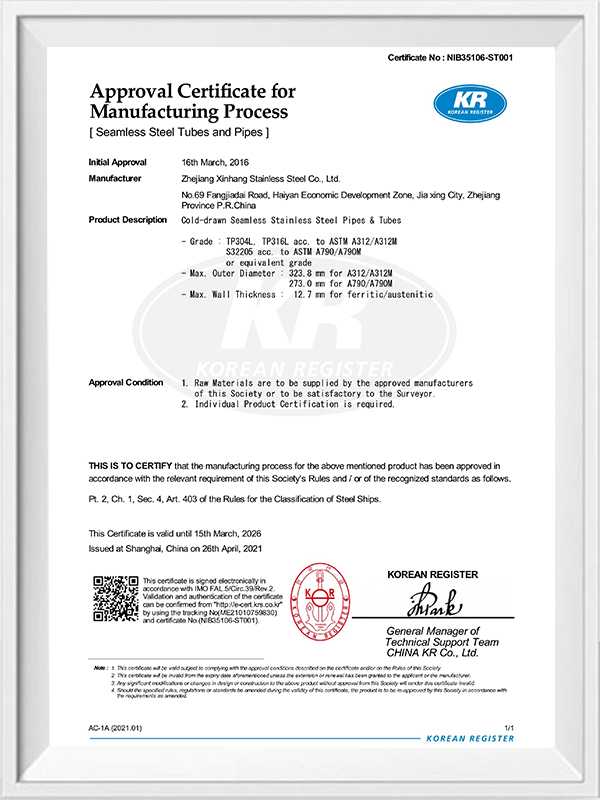

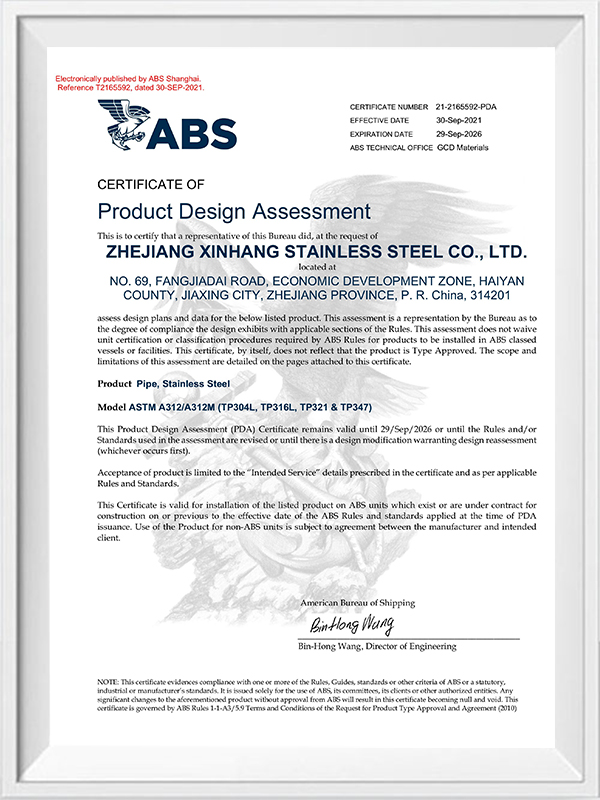

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (Abs): British Register of Shipping (LR), Deutsche Veritas (GL), Bureau veritas Society (BV), Det Norske (DNV), Coreanica Register of Shipping (KR) officina certification.

Pelagus products includere immaculatam ferro, pipe caerimonias, flanges, valvulae, etc., quae late in PETROLEUM, chemical industria, nuclei industria, urget, shippuilding, nuclei, cibo, saltu, electrica, et alimentis, mechanica apparatibus, et aliis agris. In comitatu adhaeret ad corporatum tenet de "qualis est superessendam, fama pro progressionem" et animo serves omnis mos creare win-vincere situ.

Optimum flare instrumentum electionis pro immaculata ferro Tubing Utere summus leverage 37° (AN/JIC) vel 45° (SAE) subtilius instrumentum ad ferrum ignitum aestimatum est, paribus drom...

VisumSolum versus: quomodo ferro intemeratam pactionem tibiam sine saccharo et scillam? Fistula enim ferro incorruptissima opus est, certissima via ad emundandum, corrosio repugnans, rimis stri...

VisumDirectum responsum: quid "canalem ferream immaculatam pressionem rating" revera significat? Fistula ferrea immaculata unam pressionem universalem rating non habet. Recta "incorrupta ...

VisumNos te numquam participes vestri email oratio et vos

Potest opt e aliquo tempore promittimus.