Orificium flanges sunt unum ex parcus modo mensuræ fluxus. Sunt piping systems in elementis, posita inter fistula sectiones. In orificium flange continet orificium laminam de CCCXVI immaculatam ferro inter tailpiece et filum fragmen unionem.

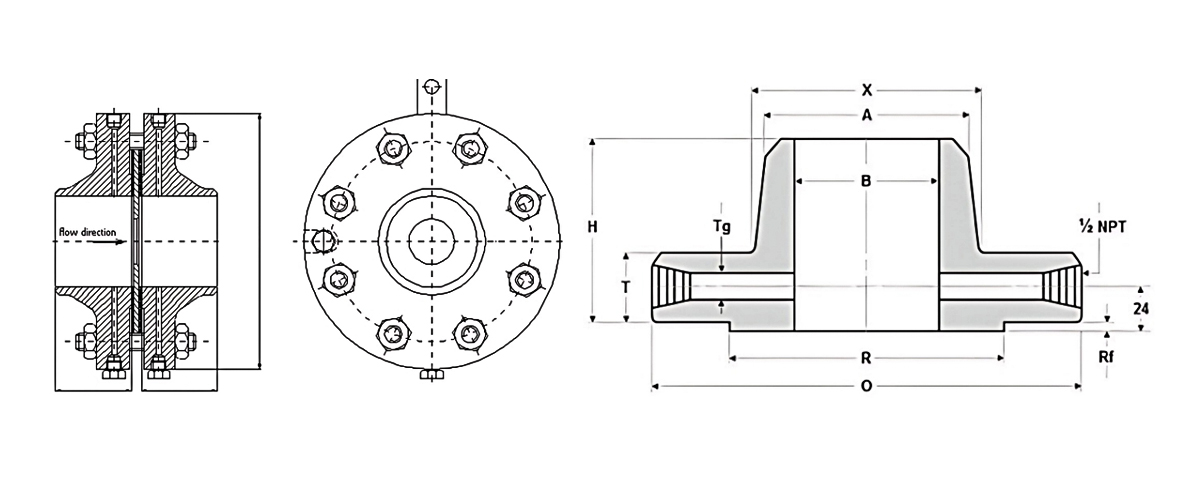

An orificium laminam cum peperit adhibetur ad fluxus imperium et influunt reductionem. Orificium laminam potest terebravisse ad sever aut sinistram blank. Partes pressura sunt typice in II utrimque, directe opposita se et sint machined in orificium LABIS. Hoc facit separatam orificium carriers vel tappings in pipe muro necesse.

Orificium Flances constructum a durabile materiae velut ipsum vel immaculatam ferro, ut Vivacitas et reliability diverse operational conditionibus. Illi ludere a vitalis munus in applications requiring praecisa fluxus rates. Sunt late usus est in industrias ut: chemicals et petrochemicals, liquefacta naturalis Gas facilities, potestate, fluxus-control systems generationem, etc.

Introductio

| Vexillum | ASME B16.5, ASME B16.36, ASME B16.47,MSS-44, API605, API6a, EN1092-1, DIN 2527, DIN2573, DIN 2575, DIN 2560, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2673, DIN 2652, DIN 2653, DIN 2655m DIN 2656, DIN 2641, DIN 2642, DIN 2502, DIN2503, DIN 2565, DIN 2566, DIN 2567, DIN 2568, DIN 2569, DIN 2627, DIN 2628, DIN2629, DIN 2638, DIN 243, DIN 2544, DIN 2545, DIN 28115, DIN 28117, DIN 2558, DIN 2561, DIN 86029, DIN 86057, BS MDLX, BS 4504-3.1, Gost12820, Gost12821, Jis B2220, JIS B2201. etc. |

| Materia | MXX, MXLV, 16mn, 25Crmo, 42Crmo, SS304, SS316, 17-4, aes MS58, Alu (VI) LXI, etc. |

| Superficies | Superficiem curatio est Northmanni nigra; POLIENTIA |

| Genus | Mori Forging / Free Forging, CNC Machining |

| magnitudo | I "-24" |

| Delivery Tempus | Intra 5-30 diebus post acceptam PROMUTUUS |

| Stipare | Lobortis buxum aut lignea arca archa |

| Applicatio | Maxime usus est in Mining, Metallurgical, Caementa, Chemicals, Construction, Aedificium Materials, Electric Power, Telecommunications, Textiles, et translationem departments. |

Genus CCC

| Nps | Exterius dia. | Flange densissima. | Hub Od | Weld collum OD | Welding collum longitudinem | RF dia. | Altitudo RF | Fulmen | Orificium foraminis dia | Neminem de BOLts | Dia Bulla Seras | RF Tandem | SOLARIUM | ISO debiles magnitudine | Pondus KG |

| - | O | T | X | A | H | R | - | - | TG | - | - | - | - | - | - |

| 1 | 125 | 36.6 | 54 | 33.4 | 81 | 50.8 | 2 | 88.9 | 6.4 | 4 | 5/8 | 125 | 3/4 | M16 | 4.5 |

| I ½ | 155 | 36.6 | 70 | 48.3 | 84 | 73 | 2 | 114.3 | 6.4 | 4 | 3/4 | 135 | 7/8 | M20 | 6.5 |

| 2 | 165 | 36.6 | 84 | 60.3 | 84 | 92.1 | 2 | 127 | 6.4 | 8 | 5/8 | 125 | 3/4 | M16 | 7 |

| II obolum | 190 | 36.6 | 100 | 73 | 87 | 104.8 | 2 | 149.2 | 6.4 | 8 | 3/4 | 135 | 7/8 | M20 | 7.5 |

| 3 | 210 | 36.6 | 117 | 88.9 | 87 | 127 | 2 | 168.3 | 9.5 | 8 | 3/4 | 135 | 7/8 | M20 | 9.4 |

| 4 | 255 | 36.6 | 146 | 114.3 | 90 | 157.2 | 2 | 200 | 12.7 | 8 | 3/4 | 135 | 7/8 | M20 | 13.2 |

| 6 | 320 | 36.6 | 206 | 168.3 | 98 | 215.9 | 2 | 269.9 | 12.7 | 12 | 3/4 | 135 | 7/8 | M20 | 14.6 |

| 8 | 380 | 39.7 | 260 | 219.1 | 110 | 269.9 | 2 | 330.2 | 12.7 | 12 | 7/8 | 145 | 1 | M24 | 30 |

| 10 | 445 | 46.1 | 321 | 273 | 116 | 323.8 | 2 | 387.3 | 12.7 | 16 | 1 | 165 | 11/8 | M27 | 41 |

| 12 | 520 | 49.3 | 375 | 323.8 | 129 | 381 | 2 | 450.8 | 12.7 | 16 | 11/8 | 180 | 11/4 | M30 | 62 |

| 14 | 585 | 52.4 | 425 | 355.6 | 141 | 412.8 | 2 | 514.4 | 12.7 | 20 | 11/8 | 185 | 11/4 | M30 | 84 |

| 16 | 650 | 55.6 | 483 | 406.4 | 144 | 469.9 | 2 | 571.5 | 12.7 | 20 | 11/4 | 195 | 13/8 | M33 | 111 |

| 18 | 710 | 58.8 | 533 | 457 | 1557 | 533.4 | 2 | 628.6 | 12.7 | 24 | 11/4 | 205 | 13/8 | M33 | 138 |

| 20 | 775 | 62 | 587 | 508 | 160 | 584.2 | 2 | 685.8 | 12.7 | 24 | 11/4 | 215 | 13/8 | M33 | 171 |

| 24 | 915 | 68.3 | 702 | 610 | 167 | 692.2 | 2 | 812.8 | 12.7 | 24 | 11/2 | 240 | 15/8 | M39 | 247 |

Genus DC

| Nps | Exterius dia. | Flange densissima. | Hub Od | Weld collum OD | Welding collum longitudinem | RF dia. | Altitudo RF | Fulmen | Orificium foraminis dia | Neminem de BOLts | Dia Bulla Seras | RF Tandem | SOLARIUM | ISO debiles magnitudine | Pondus KG |

| - | O | T | X | A | H | R | - | - | TG | - | - | - | - | - | - |

| 1 | 125 | 36.6 | 54 | 33.5 | 81 | 50.8 | 7 | 88.9 | 6.4 | 4 | 5/8 | 125 | 3/4 | M16 | 5.5 |

| I ½ | 155 | 36.6 | 70 | 48.3 | 84 | 73 | 7 | 114.3 | 6.4 | 4 | 3/4 | 135 | 7/8 | M20 | 7.8 |

| 2 | 165 | 36.6 | 84 | 60.3 | 84 | 92.1 | 7 | 127 | 6.4 | 8 | 5/8 | 125 | 3/4 | M16 | 8.3 |

| II obolum | 190 | 36.6 | 100 | 73 | 87 | 104.8 | 7 | 149.2 | 6.4 | 8 | 3/4 | 135 | 7/8 | M20 | 10.8 |

| 3 | 210 | 36.6 | 117 | 88.9 | 87 | 127 | 7 | 168.3 | 9.5 | 8 | 3/4 | 135 | 7/8 | M20 | 12.6 |

| 4 | 275 | 38.1 | 152 | 114.3 | 102 | 157.2 | 7 | 215.9 | 12.7 | 8 | 7/8 | 150 | 1 | M24 | 19 |

| 6 | 355 | 47.7 | 222 | 168.3 | 117 | 215.9 | 7 | 292.1 | 12.7 | 12 | 1 | 180 | 11/8 | M27 | 37 |

| 8 | 420 | 55.6 | 273 | 219.1 | 133 | 269.9 | 7 | 349.2 | 12.7 | 12 | 11/8 | 195 | 11/4 | M30 | 53 |

| 10 | 510 | 63.5 | 343 | 273 | 152 | 323.8 | 7 | 431.8 | 12.7 | 16 | 11/4 | 220 | 13/8 | M33 | 86 |

| 12 | 560 | 66.7 | 400 | 323.8 | 156 | 381 | 7 | 489 | 12.7 | 20 | 11/4 | 230 | 13/8 | M33 | 102 |

| 14 | 605 | 69.9 | 432 | 355.6 | 165 | 412.8 | 7 | 527 | 12.7 | 20 | 13/8 | 240 | 11/2 | M36 | 150 |

| 16 | 685 | 76.2 | 495 | 406.4 | 178 | 469.9 | 7 | 603.2 | 12.7 | 20 | 11/2 | 260 | 15/8 | M39 | 190 |

| 18 | 745 | 82.6 | 546 | 452.2 | 184 | 533.4 | 7 | 654 | 12.7 | 20 | 15/8 | 280 | 13/4 | M42 | 240 |

| 20 | 815 | 88.9 | 610 | 508 | 190 | 584.2 | 7 | 723.9 | 12.7 | 24 | 15/8 | 300 | 13/4 | M42 | 295 |

| 24 | 940 | 101.6 | 718 | 609.6 | 203 | 692.2 | 7 | 838.2 | 12.7 | 24 | 17/8 | 335 | 2 | M48 | 365 |

Genus CM

| Nps | Exterius dia. | Flange densissima. | Hub Od | Weld collum OD | Welding collum longitudinem | RF dia. | Altitudo RF | Fulmen | Orificium foraminis dia | Neminem de BOLts | Dia Bulla Seras | RF Tandem | SOLARIUM | ISO debiles magnitudine | Pondus KG |

| - | O | T | X | A | H | R | - | - | TG | - | - | - | - | - | - |

| 1 | 150 | 38.1 | 52 | 33.5 | 83 | 50.8 | 7 | 101.6 | 6.4 | 4 | 7/8 | 150 | 1 | M24 | 5.4 |

| I ½ | 180 | 38.1 | 70 | 48.3 | 89 | 73 | 7 | 123.8 | 6.4 | 4 | 1 | 160 | 11/8 | M27 | 7.8 |

| 2 | 215 | 38.1 | 105 | 60.3 | 102 | 92.1 | 7 | 165.1 | 6.4 | 8 | 7/8 | 150 | 1 | M30 | 11..5 |

| II obolum | 245 | 41.3 | 124 | 73 | 105 | 104.8 | 7 | 190.5 | 6.4 | 8 | 1 | 165 | 11/8 | M27 | 15.8 |

| 3 | 240 | 38.1 | 127 | 88.9 | 102 | 127 | 7 | 190.5 | 9.5 | 8 | 7/8 | 150 | 1 | M24 | 22 |

| 4 | 290 | 44.5 | 159 | 114.3 | 114 | 157.2 | 7 | 235 | 12.7 | 8 | 11/8 | 180 | 11/4 | M30 | 22 |

| 6 | 380 | 55.6 | 235 | 168.3 | 140 | 215.9 | 7 | 317.5 | 12.7 | 12 | 11/8 | 195 | 11/4 | M30 | 70 |

| 8 | 470 | 63.5 | 298 | 219.1 | 162 | 269.9 | 7 | 393.7 | 12.7 | 12 | 13/8 | 230 | 11/2 | M36 | 119 |

| 10 | 545 | 69.9 | 368 | 273 | 184 | 323.8 | 7 | 469.9 | 12.7 | 16 | 13/8 | 240 | 11/2 | M36 | 204 |

| 12 | 610 | 79.4 | 419 | 323.8 | 200 | 381 | 7 | 533.4 | 12.7 | 20 | 13/8 | 260 | 11/2 | M36 | 303 |

| 14 | 640 | 85.8 | 451 | 355.6 | 213 | 412.8 | 7 | 558.8 | 12.7 | 20 | 11/2 | 280 | 15/8 | M39 | 400 |

| 16 | 705 | 88.9 | 508 | 406.4 | 216 | 469.9 | 7 | 616 | 12.7 | 20 | 15/8 | 290 | 13/4 | M42 | 510 |

| 18 | 785 | 101.9 | 565 | 457.2 | 229 | 533.4 | 7 | 685.8 | 12.7 | 20 | 17/8 | 330 | 2 | M48 | 738 |

| 20 | 855 | 108 | 622 | 508 | 248 | 584.2 | 7 | 749.3 | 12.7 | 20 | 2 | 355 | 21/8 | M52 | 932 |

| 24 | 1040 | 139.7 | 749 | 609.6 | 292 | 692.2 | 7 | 901.7 | 12.7 | 20 | 21/2 | 445 | 25/8 | M64 | 1511 |

Classis MD

| Nps | Exterius dia. | Flange densissima. | Hub Od | Weld collum OD | Welding collum longitudinem | RF dia. | Altitudo RF | Fulmen | Orificium foraminis dia | Neminem de BOLts | Dia Bulla Seras | RF Tandem | SOLARIUM | ISO debiles magnitudine | Pondus KG |

| - | O | T | X | A | H | R | - | - | TG | - | - | - | - | - | - |

| 1 | 150 | 38.1 | 52 | 33.5 | 83 | 50.8 | 7 | 101.6 | 6.4 | 4 | 7/8 | 150 | 1 | M24 | 5.4 |

| I ½ | 180 | 38.1 | 70 | 48.3 | 89 | 73 | 7 | 123.8 | 6.4 | 4 | 1 | 160 | 11/8 | M27 | 7.8 |

| 2 | 215 | 38.1 | 105 | 60.3 | 102 | 92.1 | 7 | 165.1 | 6.4 | 8 | 7/8 | 150 | 1 | M24 | 11.5 |

| II obolum | 245 | 41.3 | 124 | 73 | 105 | 104.8 | 7 | 190.5 | 6.4 | 8 | 1 | 165 | 11/8 | M27 | 15.8 |

| 3 | 265 | 47.7 | 133 | 88.9 | 117 | 127 | 7 | 203.2 | 9.5 | 8 | 11/8 | 185 | 11/4 | M30 | 22 |

| 4 | 310 | 54 | 162 | 114.3 | 124 | 157.2 | 7 | 241.3 | 12.7 | 8 | 11/4 | 205 | 13/8 | M33 | 22 |

| 6 | 395 | 82.6 | 229 | 168.3 | 171 | 215.9 | 7 | 317.5 | 12.7 | 12 | 13/8 | 265 | 11/2 | M36 | 70 |

| 8 | 485 | 92.1 | 292 | 219.1 | 213 | 269.9 | 7 | 393.7 | 12.7 | 12 | 15/8 | 300 | 13/4 | M42 | 119 |

| 10 | 585 | 108 | 368 | 273 | 254 | 323.8 | 7 | 482.6 | 12.7 | 12 | 17/8 | 345 | 1 | M48 | 204 |

| 12 | 675 | 123.9 | 451 | 32.8 | 283 | 381 | 7 | 571.5 | 12.7 | 16 | 2 | 380 | 21/8 | M52 | 303 |

| 14 | 750 | 133.4 | 495 | 355.6 | 298 | 412.8 | 7 | 635 | 12.7 | 16 | 21/4 | 415 | 23/8 | M56 | 400 |

| 16 | 825 | 146.1 | 552 | 406.4 | 311 | 469.9 | 7 | 704.8 | 12.7 | 16 | 21/2 | 450 | 25/8 | M64 | 510 |

| 18 | 915 | 162 | 597 | 457.2 | 327 | 533.4 | 7 | 774.7 | 12.7 | 16 | 23/4 | 500 | 27/8 | M72 | 738 |

| 20 | 985 | 177.8 | 641 | 508 | 356 | 584.2 | 7 | 831.8 | 12.7 | 16 | 3 | 545 | 31/8 | M76 | 932 |

| 24 | 1170 | 203.2 | 762 | 609.6 | 406 | 692.2 | 7 | 990.6 | 12.7 | 16 | 31/2 | 620 | 35/8 | M90 | 1511 |

Classis MMD

| Nps | Exterius dia. | Flange densissima. | Hub Od | Weld collum OD | Welding collum longitudinem | RF dia. | Altitudo RF | Fulmen | Orificium foraminis dia | Neminem de BOLts | Dia Bulla Seras | RF Tandem | SOLARIUM | ISO debiles magnitudine | Pondus KG |

| - | O | T | X | A | H | R | - | - | TG | - | - | - | - | - | - |

| 1 | 160 | 38.1 | 57 | 33.5 | 92 | 50.8 | 7 | 108 | 6.4 | 4 | 7/8 | 150 | 1 | M24 | 6.5 |

| I ½ | 205 | 44.5 | 79 | 48.3 | 111 | 73 | 7 | 146 | 6.4 | 4 | 11/8 | 180 | 11/4 | M30 | 13 |

| 2 | 235 | 50.8 | 95 | 60.3 | 127 | 92.1 | 7 | 171.4 | 6.4 | 8 | 1 | 185 | 11/8 | M27 | 19 |

| II obolum | 265 | 57.2 | 114 | 73 | 143 | 104.8 | 7 | 196.8 | 6.4 | 8 | 11/8 | 205 | 11/4 | M30 | 24 |

| 3 | 305 | 66.7 | 133 | 88.9 | 168 | 127 | 7 | 228.6 | 9.5 | 8 | 11/4 | 230 | 13/8 | M33 | 43 |

| 4 | 355 | 76.2 | 165 | 114.3 | 190 | 157.2 | 7 | 273 | 12.7 | 8 | 11/2 | 260 | 15/8 | M39 | 66 |

| 6 | 485 | 108 | 235 | 168.3 | 273 | 215.9 | 7 | 368.3 | 12.7 | 8 | 2 | 350 | 21/8 | M52 | 172 |

| 8 | 550 | 127 | 305 | 219.1 | 318 | 269.9 | 7 | 438.2 | 12.7 | 12 | 2 | 385 | 21/8 | M52 | 261 |

| 10 | 675 | 165.1 | 375 | 273 | 419 | 323.8 | 7 | 539.8 | 12.7 | 12 | 21/2 | 490 | 25/8 | M64 | 485 |

| 12 | 760 | 184.2 | 441 | 32.8 | 464 | 381 | 7 | 619.1 | 12.7 | 12 | 23/4 | 540 | 27/8 | M72 | 730 |

Condita in MMVII et ad Longyou oeconomica progressionem zonam, Zhejiang provincia, in MMXXII. Covers aream 130,000 quadratum metris, magis quam XXX productio lineas, CCC operarios, XX R & D populus, XXX inspectionem et annua, XX R & D populus, XXX inspectionem et annua output de 50.000 talentorum XXX.

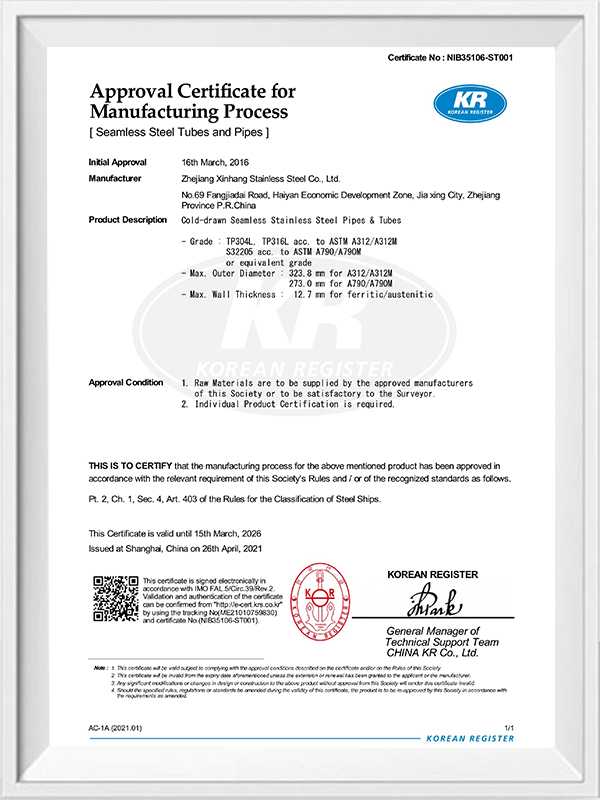

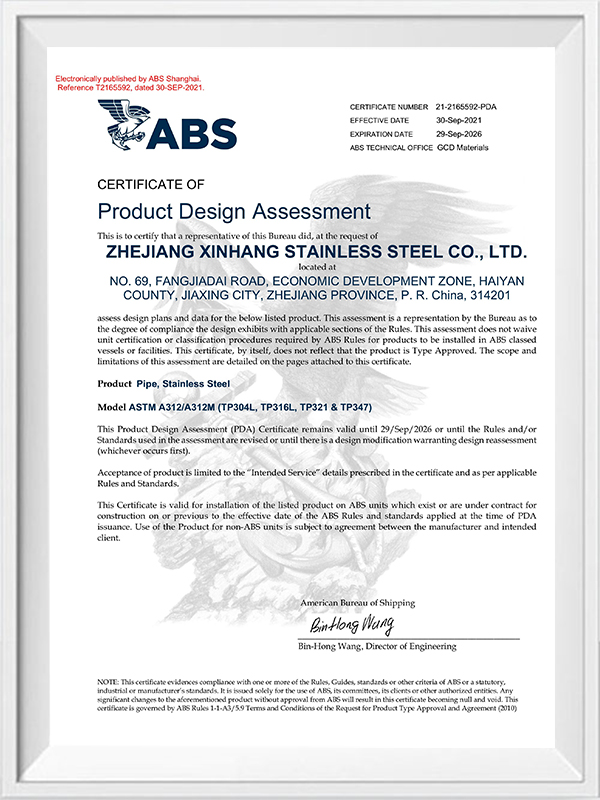

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (Abs): British Register of Shipping (LR), Deutsche Veritas (GL), Bureau veritas Society (BV), Det Norske (DNV), Coreanica Register of Shipping (KR) officina certification.

Pelagus products includere immaculatam ferro, pipe caerimonias, flanges, valvulae, etc., quae late in PETROLEUM, chemical industria, nuclei industria, urget, shippuilding, nuclei, cibo, saltu, electrica, et alimentis, mechanica apparatibus, et aliis agris. In comitatu adhaeret ad corporatum tenet de "qualis est superessendam, fama pro progressionem" et animo serves omnis mos creare win-vincere situ.

Optimum flare instrumentum electionis pro immaculata ferro Tubing Utere summus leverage 37° (AN/JIC) vel 45° (SAE) subtilius instrumentum ad ferrum ignitum aestimatum est, paribus drom...

VisumSolum versus: quomodo ferro intemeratam pactionem tibiam sine saccharo et scillam? Fistula enim ferro incorruptissima opus est, certissima via ad emundandum, corrosio repugnans, rimis stri...

VisumDirectum responsum: quid "canalem ferream immaculatam pressionem rating" revera significat? Fistula ferrea immaculata unam pressionem universalem rating non habet. Recta "incorrupta ...

VisumNos te numquam participes vestri email oratio et vos

Potest opt e aliquo tempore promittimus.